EDI 856

“Where is my order?”

It’s a question that’s familiar to any retailer with ecommerce operations. Quick and hassle-free fulfillment is what every retailer aspires to so that they can satisfy customers who have become used to two-day shipping offered by Amazon and Walmart.

Fulfillment and shipment tracking takes on even greater importance in a dropship context. When retailers aren’t shipping orders themselves, it’s critical that they know when brands are shipping their items and the location of each shipment as well.

Ecommerce platforms like Shopify and BigCommerce sync fulfillment information from carriers to brands seamlessly. With platforms like Modern Dropship, that information is passed on to retailers in real time.

But for suppliers that aren’t on those platforms and are still using legacy protocols like electronic data interchange (EDI) to manage their supply chain, what do you do? That’s when you need EDI 856 Advanced Shipment Notice documents to get the fulfillment information you need.

In this article, we’ll explain what EDI 856 documents are and why they’re used. We’ll also share an example of an EDI 856 document and walk you through it so that you know what to look for when you’re sending and receiving 856 documents with your partners.

What is an EDI 856 document?

The EDI 856 Advance Ship Notice (ASN) document is used to communicate one or more fulfillments for a single order, and includes basic shipment information such as the carrier details, tracking numbers, shipping address, and items being shipped.

856 documents are formatted in the American National Standards Institute (ANSI) x12 EDI standard in North America and EDIFACT in Europe (where they’re referred to as DESpatch ADvice or DESADV messages). Parties who receive an 856 file usually respond with an EDI 997 Functional Acknowledgement file.

Intended benefits of using EDI 856

Retailers and suppliers with legacy systems can’t track incoming and outgoing shipments without 856 files.

For wholesale shipments that move pallets of goods from suppliers to retailers, EDI 856 files are helpful to understand which of the retailer’s locations a shipment is going to and which items are included in a particular shipment. This helps retailers manage their warehouse operations so that they can accept shipments quickly and stock them in their warehouses efficiently.

For dropship shipments that are sent from suppliers directly to customers, 856 files are critical for retailers to understand when orders are being fulfilled. The tracking information that’s included in an 856 file gives them visibility into an order’s delivery date, which they can provide to customers.

Drawbacks of using EDI 856

856 files may have a lot of utility for retailers and suppliers that already manage their trade operations on EDI, but it’s important to recognize the significant drawbacks that come with EDI:

- EDI is time consuming to set up for new brands

EDI 856 files have no utility unless both trading partners have EDI implemented in their systems. So if you’re looking to trade with a hot new brand that’s running on Shopify, you have to wait for them to implement EDI. Unfortunately, this can take three to four months on average. - EDI is expensive to implement

The EDI developer ecosystem is very small, which makes every new implementation cost-prohibitive for new brands.

EDI 856 example

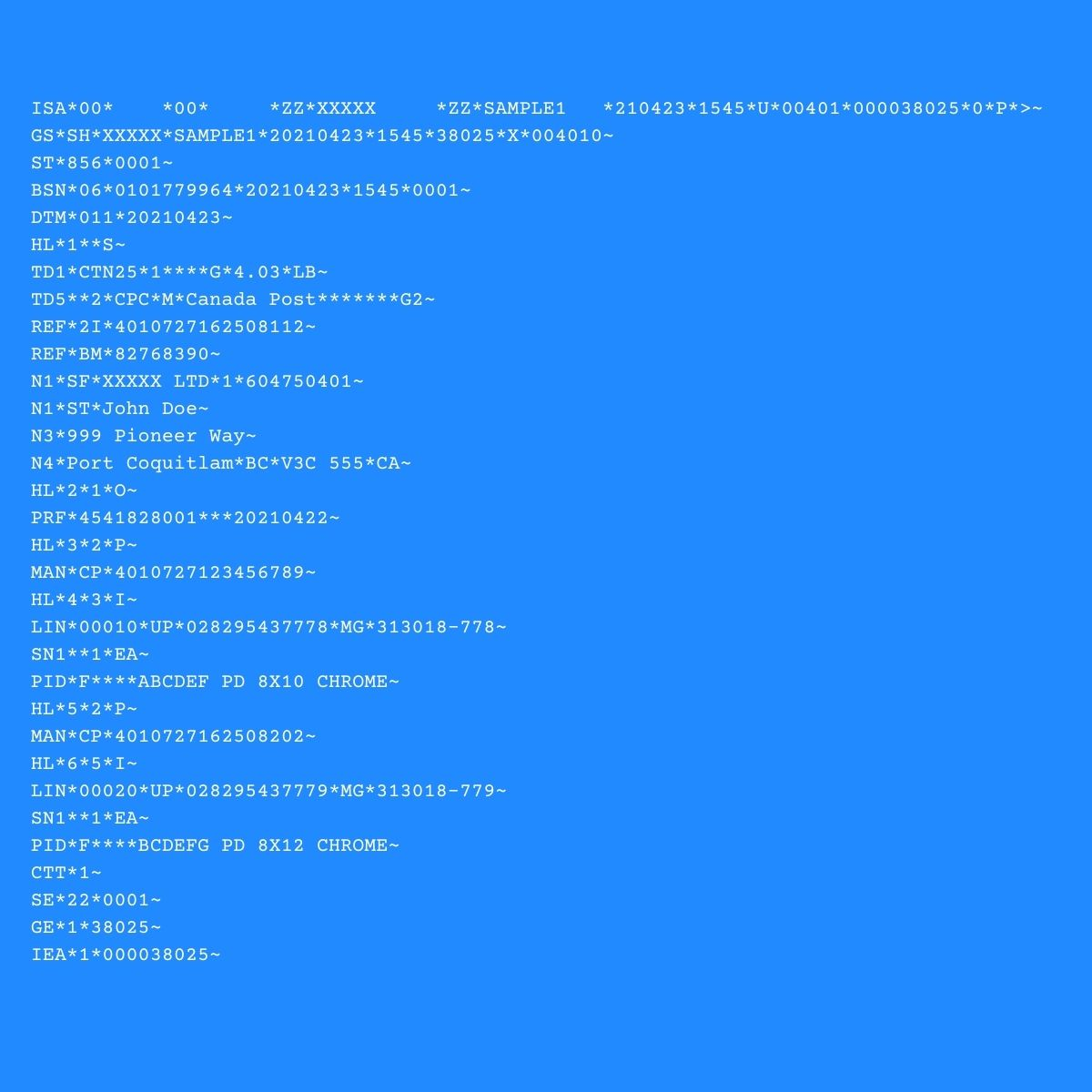

Here’s a sample EDI 856 file for dropship:

Don’t be alarmed; there’s a lot to unpack here. If you don’t have experience handling EDI files, it might be very confusing to try and understand them.

EDI files are made up of standardized sequences of data elements called segments. We’ll break down the most important segments so that you’ll be able to understand any 856 file at a glance.

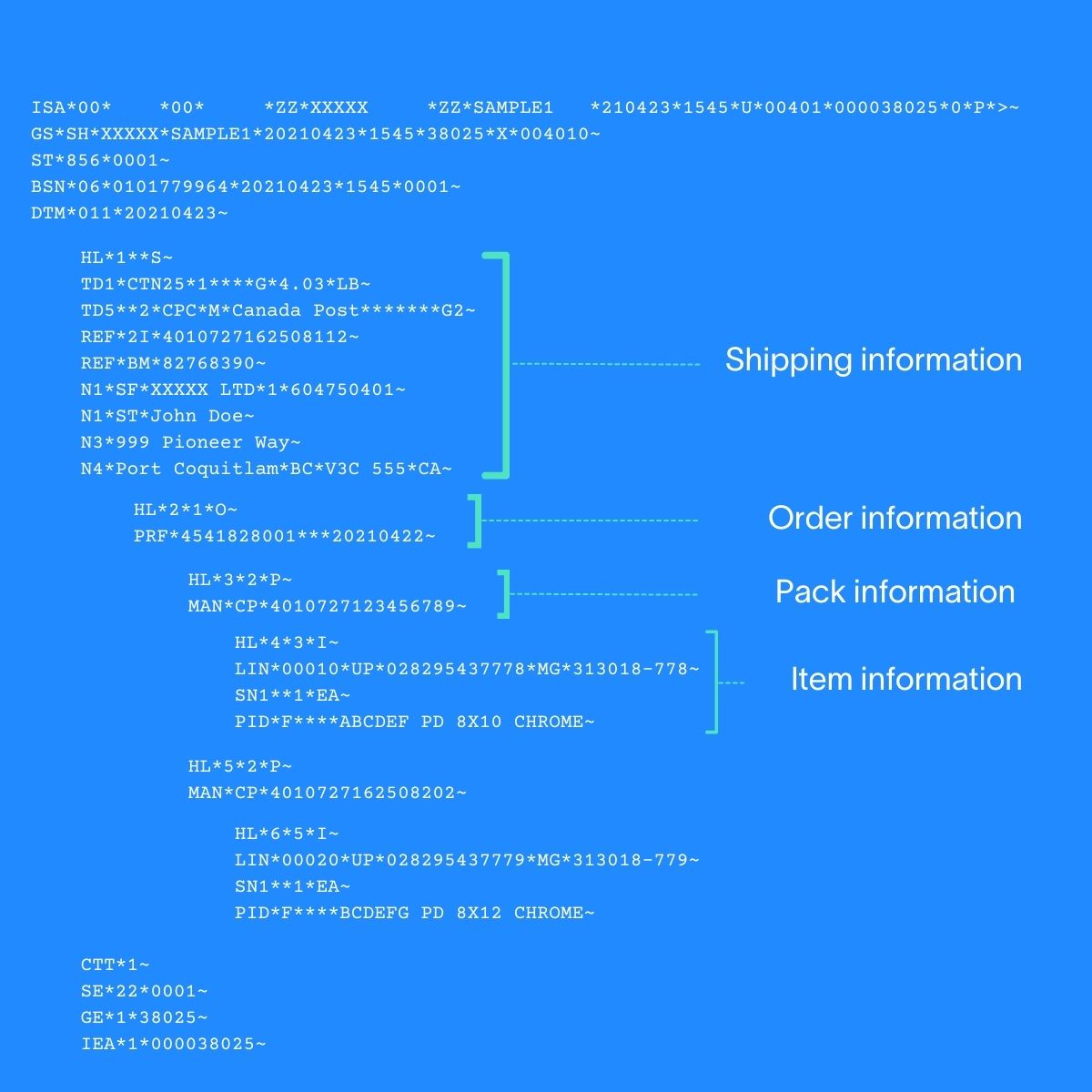

EDI 856 files are a little different compared to other EDI files (like EDI 846 or EDI 850 files) in that they have a hierarchical structure that looks like this:

Similar to other EDI files, EDI 856 files are denoted by the transaction set identifier code in the first element of the ST segment.

Each section in the hierarchical structure of an EDI file is denoted by the HL segment header, which stands for Hierarchical Level. Each HL loop has its own segment identifier in the first line of the loop, which influences the hierarchy you see in the file.

- S denotes Shipment information - the shipment’s routing information, including its destination, and its associated carrier information.

- O denotes Order - which order the shipment is associated with.

The PRF identifier in this loop refers to the purchase order number associated with the order. - P denotes Pack - the package that contains the items in the shipment.

The CP identifier refers to the Carrier Package ID. This can help you cross-reference packages in an order when you or your customer receives them. - I denotes Item - the products that are in each package.

In this example, products are identified by their UPC code (UP). PID (Product Description/Item Description) is the segment identifier that contains the product’s information.

In case you’re curious about the other segment identifiers and qualifiers that are part of this EDI transaction, like BSN, CTT, DTM, LIN loops, and more, check out our Support article that breaks this document down further.